Robotics

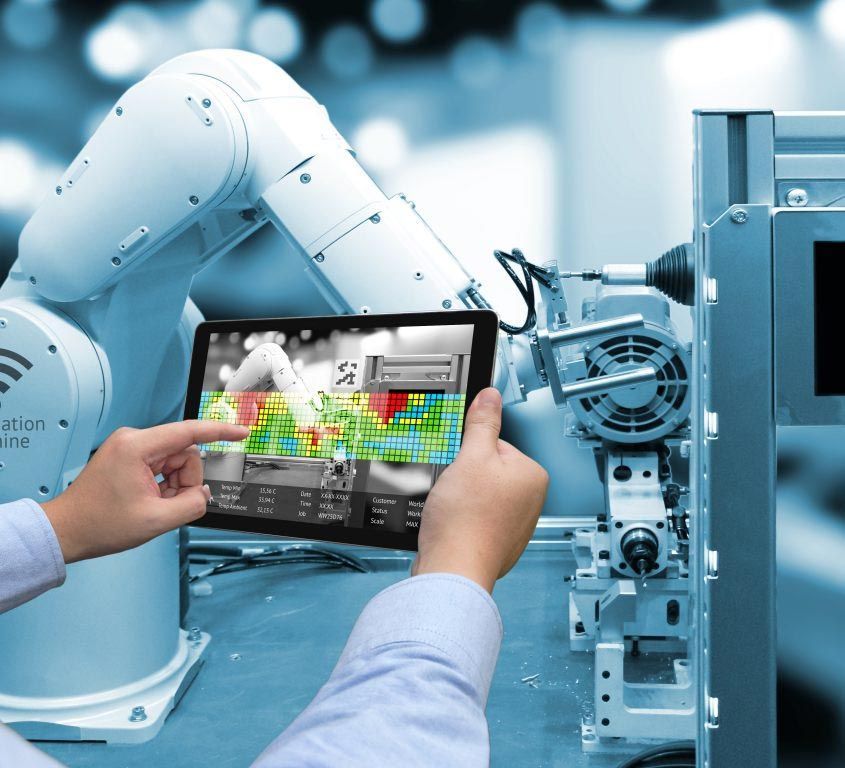

Omron LD mobile robotics application

-

Domain

Distribution center – order preparation services

-

Mandate

The objective of the project was to minimize the loss of time for order pickers traveling to the picking area and to the packing area.

-

Main Challenges

- Rapidly deploy in prototyping and validate gain estimates

- Test and adapt parking and travel equipment and strategy in the real work environment

- Determine the number of mobile robots and charging stations required in the full deployment phase

-

Solutions Provided

- Integration of autonomous mobile robots OMRON LD-105-CT

- Design, manufacturing and testing of new generation trolleys and their parking spaces

- Integration of Mobile Planner and Enterprise Manager IT solutions

Robotic pancake handling

-

Domain

Eating

-

Mandate

The objective of the project was to carry out the transfer between two stations involved in the process of manufacturing pancakes with filling.

-

Main Challenges

- High production rate

- Handle 6 products simultaneously on a moving conveyor

- Limited workspace

-

Solutions Provided

- Integration of a Stäubli Clean Room robot arm

- Design of a tailor-made manipulator

- Integration of a vision system to detect the size of pancakes

Assembly line for the automotive industry

-

Domain

Automotive, production line

-

Mandate

The objective of the project was to design a line for assembling and shaping car turbo segments on their axis.

-

Main Challenges

- High production rate

- High precision

- Line autonomy

- Model Variety

-

Solutions Provided

- Integration of the CRFM

- Specific insertion tools

- Optical fiber detection

- Automatic loading and unloading

- Supply conveyor

Quenching Furnace Loading

-

Domain

Manufacturing industry

-

Mandate

The objective of the project was to feed glass pane into a tempering furnace. Sandblasting of the glass edges also had to be done during the tempering process.

-

Main Challenges

- Integration of the automated line in a restricted environment

- Adapt to around twenty glass sizes

- Handle glass panes without breaking them

- Do not leave any residual marks (scratches, cracks)

-

Solutions Provided

- Integration of a Fanuc robot arm

- Design of a tailor-made manipulator

- Partnership development of tailor-made suction cups

- Glass center and rim identification system

- Automation of sandblaster movement

- Staff training in programming software

Groupe Claret

Our Products

Robotics

LEARN MORE

Automating

LEARN MORE

Products Distributed

LEARN MORERobotics

LEARN MOREAutomating

LEARN MORENEWSLETTER SIGN-UP

STAY UP TO DATE WITH THE CLARET GROUP

Stay at the forefront of innovation and industry trends with the Claret Group. Receive timely updates, insights and news to help your business succeed.

Newsletter Subscription

Thank you for subscribing.

40 years of excellence in machining, robotics and automation. Trusted partners in specialized machines and precision components.

QUICK LINKS

All Rights Reserved | Claret Group | Website designed and supported by The Website Store